Free guide only available to individuals working directly for an abattoir operation and subject to availability. Offer can be withdrawn at any time without notice.

10-point guide to reducing primary chilling weight losses with humidification

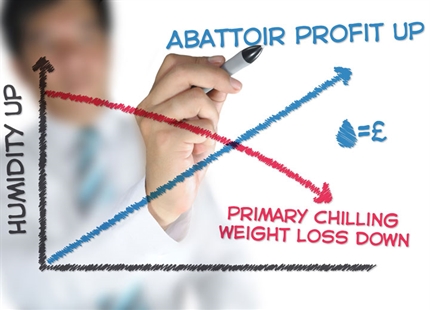

Evaporative weight losses from carcasses during primary chilling can account for between 1.5-3% of total product weight. This has a significant impact on product yield and the profitability of an abattoir operation.

Cold store humidity has been widely accepted as having a great impact on evaporative losses but managing humidity levels in such a cold environment is complex, especially given directives on spray chilling.

As a global leader in humidification technology and expertise, Condair has developed a humidification strategy that successfully manages the air humidity within a primary chilling area. By maintaining a high air humidity with this system, evaporative losses can be reduced to 1%.

This document presents an introductory 10-point guide for abattoir managers on how to correctly humidify a primary chilling operation.

Complete this form to receive your FREE copy

You may also be interested in...

Abattoir humidification

Reducing weight loss during carcass chill down to less than 1%.

Read more...Reduce primary chilling weight loss

Complete the form to get a personalised ROI projection for humidifying an abattoir's primary chilling area.

Read more...JetSpray reduces carcass weight loss

Condair’s JetSpray humidifier is helping abattoir equipment specialists, GM Steel, reduce carcass moisture loss after slaughter by up to 1.5%. By mai...

Read more...JetSpray compressed air & water spray humidifier

Robust operation without the need for RO water. Compressed air ensures very rapid evaporation without the risk of drips.

Read more...