Abattoir humidification to reduce evaporative losses

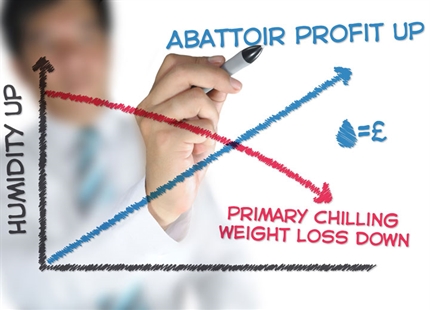

When a freshly slaughtered carcass is initially chilled to its storage temperature, it will lose weight through moisture loss to the atmosphere. Depending on the chilling process, this can be up to 3% of its overall weight. The highest losses will occur in the early stages when the temperature difference between the carcass and its surrounding chill store atmosphere is at its greatest.

By raising the humidity of the air around the carcasses to between 90-95%RH moisture loss from the meat is inhibited and weight losses can be reduced to less than 1%,

This will have an immediate impact on the profitability of an abattoir operation, as it can stop around 4kg of product evaporating from a typical side of beef during the chill down process.

As well as improving profits through reduced weight loss a higher humidity in a chill store will improve the thermal conductivity of the air. This results in the carcass reaching its storage temperature more rapidly, which in turn reduces refrigeration energy costs and inhibits microbial growth on the meat.

Get a FREE 10-point guide to reducing evaporative losses during primary chilling with humidity control

This document presents an introductory step-by-step approach for abattoir managers on how to correctly humidify a primary chilling operation.

Benefits of Condair humidification in abattoirs include:

- Reduction in primary cooling weight losses to around 1%

- Immediate increase in profitability

- Improved thermal transfer from the carcass and shorter chill cyles

- Reduced refrigeration energy costs from faster cooling

- Reduced microbial growth from faster cooling

- Extremely hygienic product design for total confidence

- Comprehensive service of advice, design, supply, installation, commissioning, maintenance and spares supply

Get expert advice on abattoir humidity control

You may be also interested in...

Reduce primary chilling weight loss

10-point guide to minimizing evaporative losses

JetSpray reduces carcass weight loss